Entry Door Weather-proofing

Waterproof door installation is one area where manufacturer installation guidelines may not give all the details required. In the process of explaining plumb, square and level procedures, weatherproofing precautions are sometimes given little coverage. The assumption might be that such details have already been covered, but knowing a few weatherproofing “must dos” will help ensure you get the best out of your builder or renovator.

The weatherproofing process begins after framing and sheathing but before siding installation. House wrap products may be generally helpful for draft protection, but at door and window openings, additional perimeter soft flashing is required. Asphalt-impregnated roofing paper was once the standard in this application, but modern, flexible peel-and-stick moisture barrier tape yields an even better result. The idea is to prevent moisture from penetrating the structure by directing it away from the interior and providing a course of least resistance to the exterior. In perimeter tape-flashing, the base strip is applied first; the sides overlap this strip, and the top section overlaps the sides, providing a continuous water barrier.

The second level of water protection occurs before threshold installation. A threshold pan (metal flashing, this time) is a catch pan with a broad base extending the width of the door opening and a raised lip running along its interior width. This flashing is set in top-quality caulking—look for a 50-year guarantee. It is designed to stop water that might be driven under the threshold from penetrating the wood structure, or to direct water that has made its way through the weep-holes of an interlocking threshold toward the exterior.

A third barrier to water infiltration is established by applying long-lasting caulk to the interior surface of the door frame’s sides and header. If a threshold pan is not used, caulk should also be liberally applied to the base of the threshold. The benefit in doing so is extended caulk longevity due to protection from UV damage by the door frame. Caulk applied at the exterior seam between the frame and structure is exposed to UV light.

A fourth barrier is the use of metal flashing above the door header trim. The flashing extends the width of the door opening or beyond. The upper flange of the flashing lies against the width of the moisture barrier tape above the door opening. An “L” ledge extends over the depth of the door trim for its full width, and a slight downward angle of the flashing edge both prevents water from getting under the flashing and directs runoff toward the exterior. In wood or vinyl siding homes, the siding forms a counter flashing. That is, the siding is another overlapping “scale” in the door’s water armor.

Complicated? A bit, but none of these redundant layers of protection are expensive or complicated in their individual installation, and the system they provide gives real insurance against both cosmetic and structural damage that will result from undiscovered leaks.

|

Tune in to The Bob and RodMan Home Show every Saturday from 9 to 11 a.m. on 920 AM-WGKA to learn how to improve your house or apartment. RodMan is a certified home inspector, knows residential property appraisal and is a hands-on home renovator. Bob owned a roofing company, has reclaimed distressed properties for years and has Master Licenses as a plumber, electrician and HVAC mechanic. www.bobandrodman.com

Garden Gear-Up. Organize Everything You Need In One Place

Product Gallery

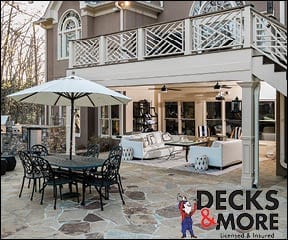

2014 Best Patio/Porches/Decks

Award-Winning Kitchens, Baths, Interior Design and More

Atlanta’s NKBA Designs of Distinction 2019 Winners

100 Things to Know Before You Remodel

What’s the simplest way to upgrade your window treatments?